-

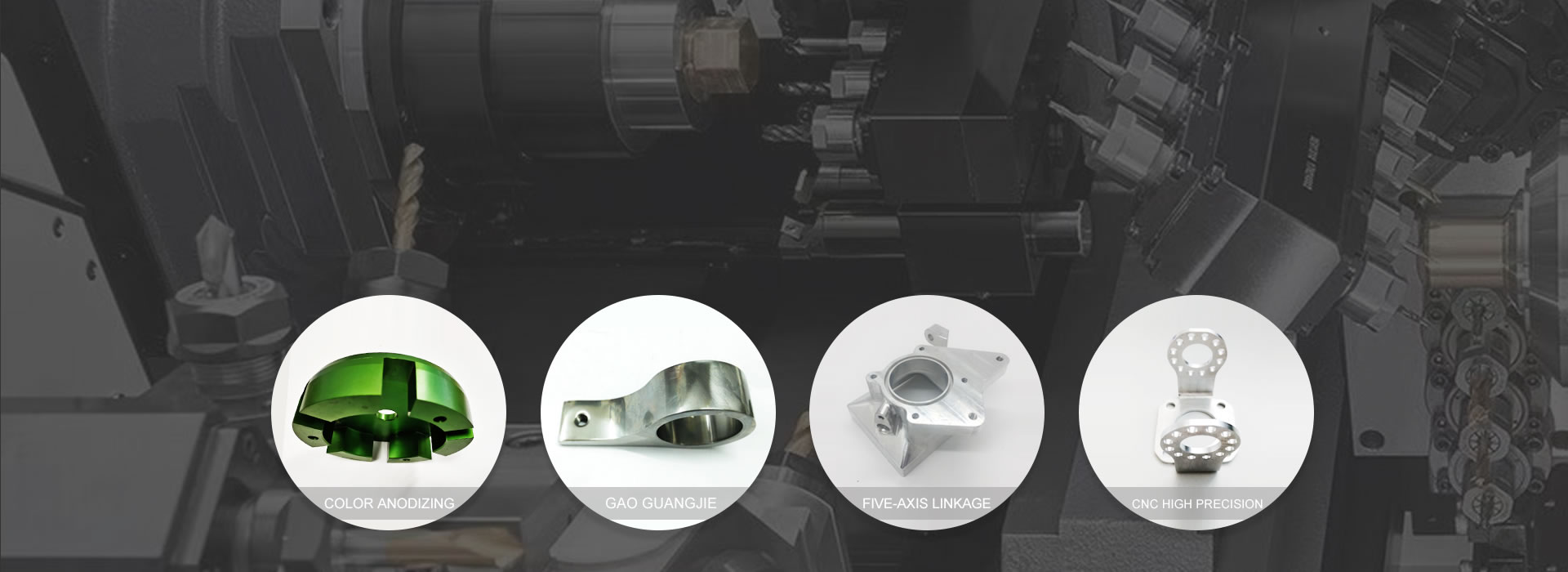

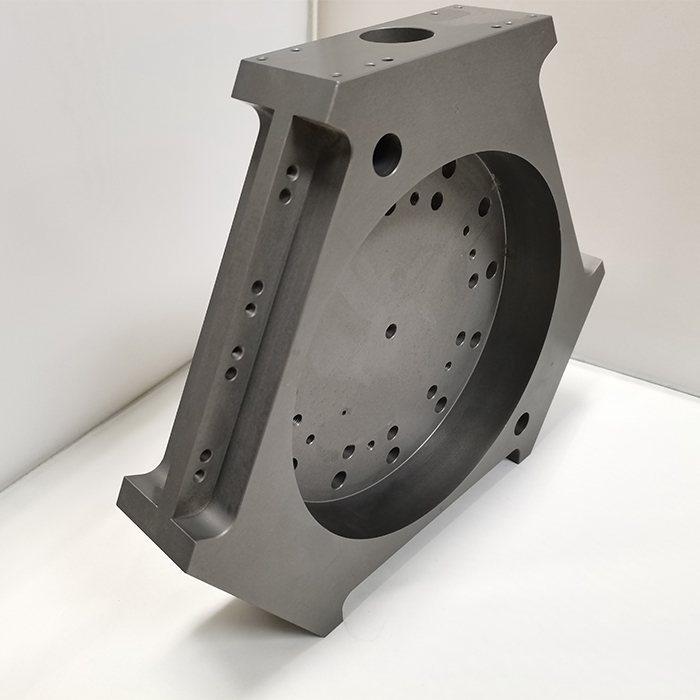

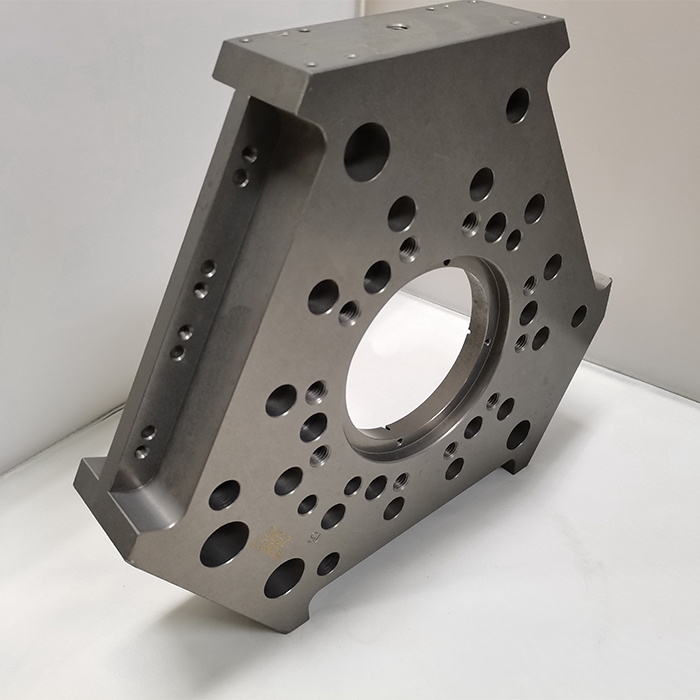

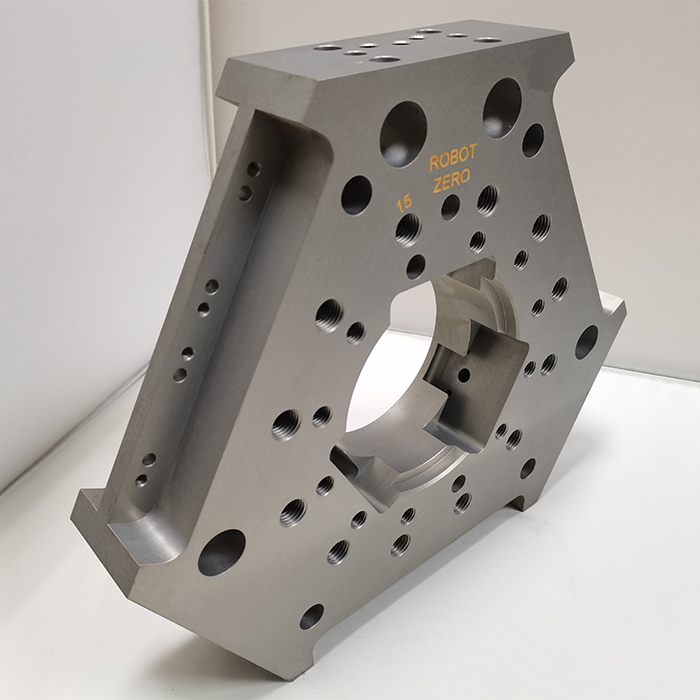

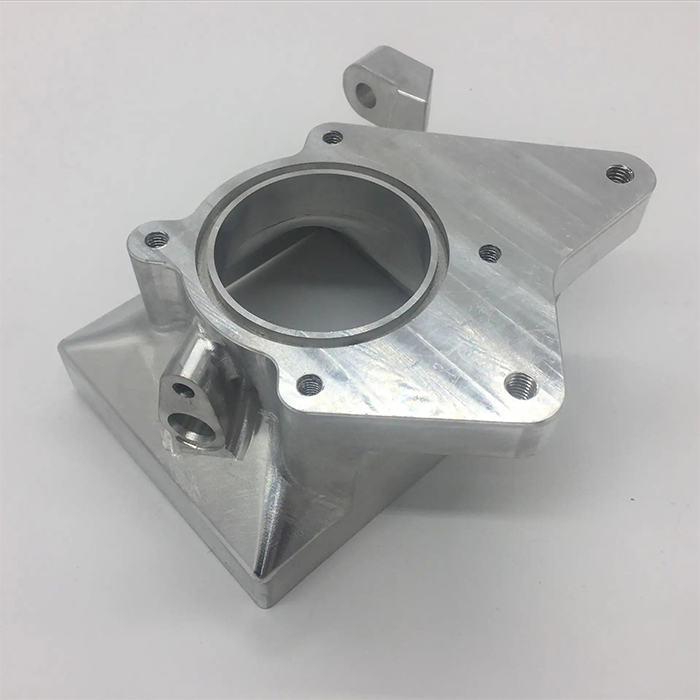

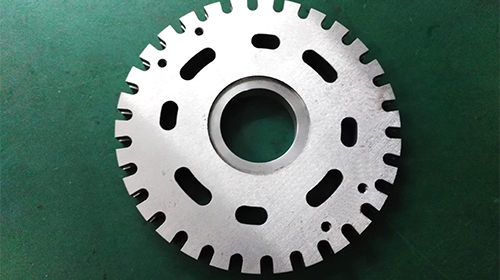

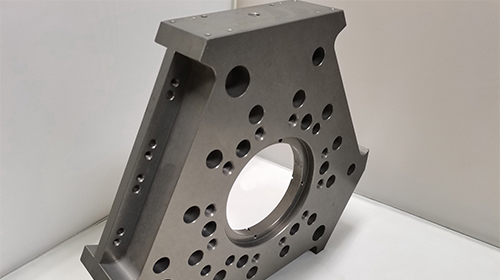

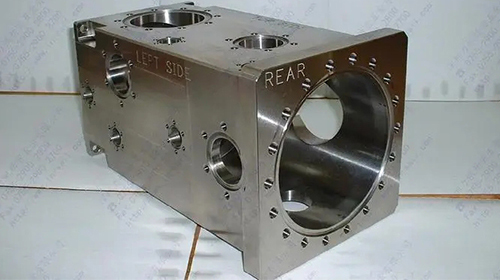

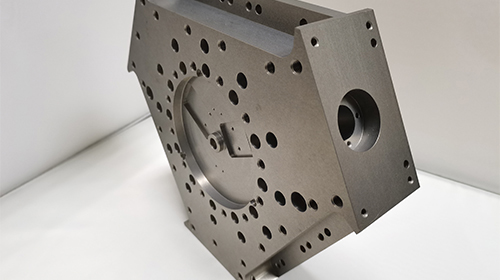

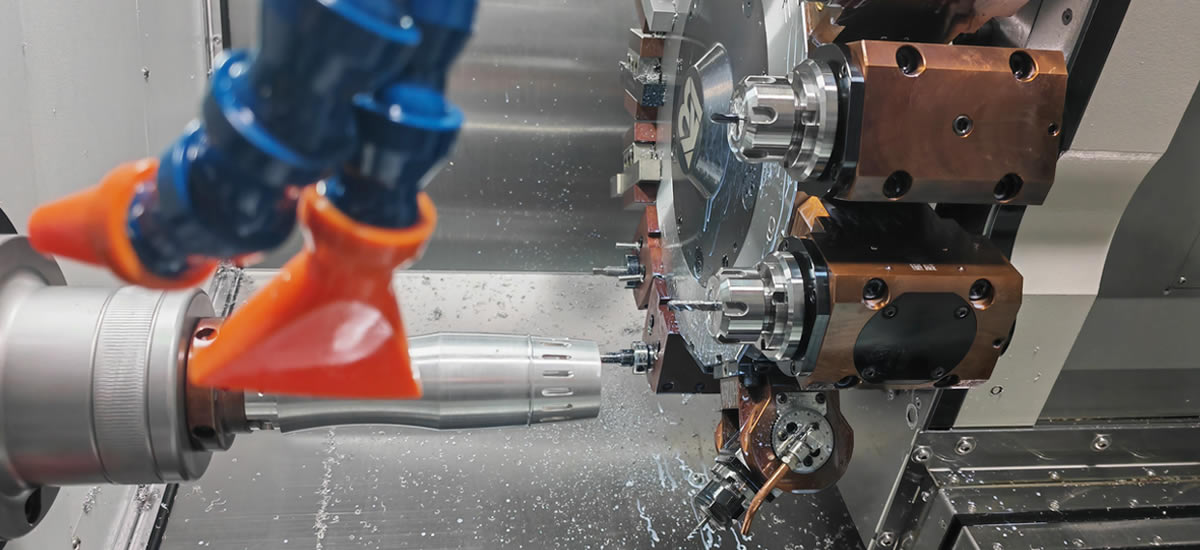

Support customization

Support non-standard customization and meet personalized customer needs.

-

Multiple specifications

Our company offers a comprehensive range of products with high precision and can deliver quickly.

-

The material is guaranteed

Good selection of components with peace of mind, quality as the foundation, and wide application.

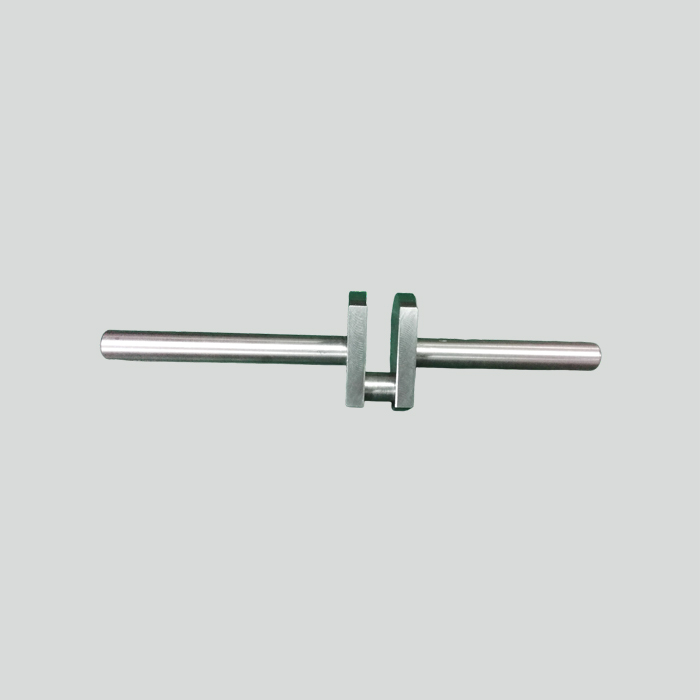

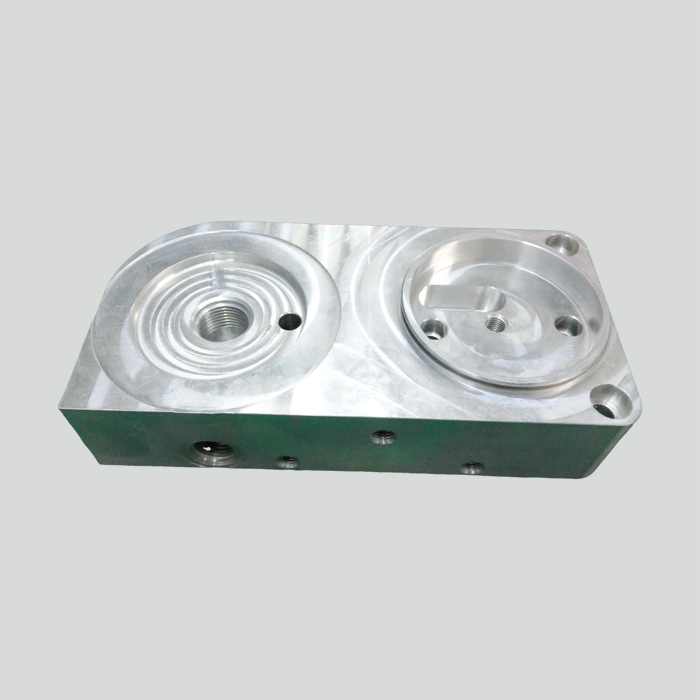

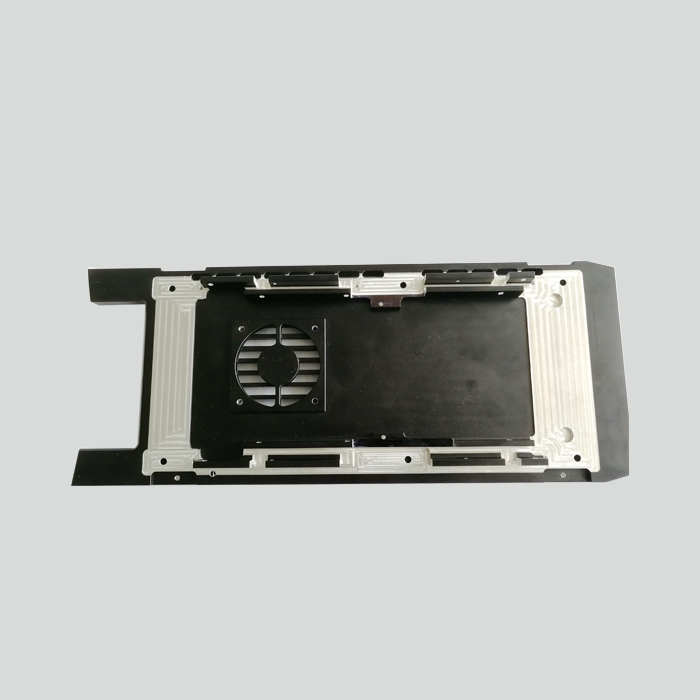

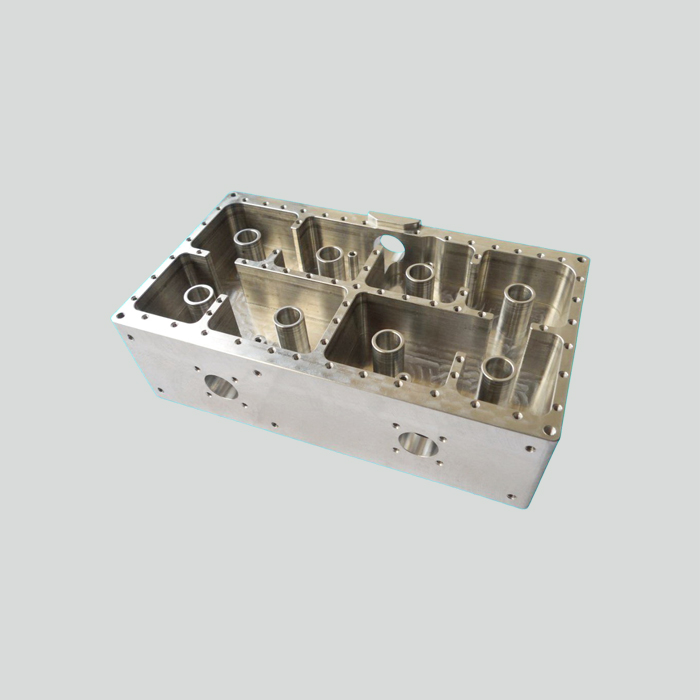

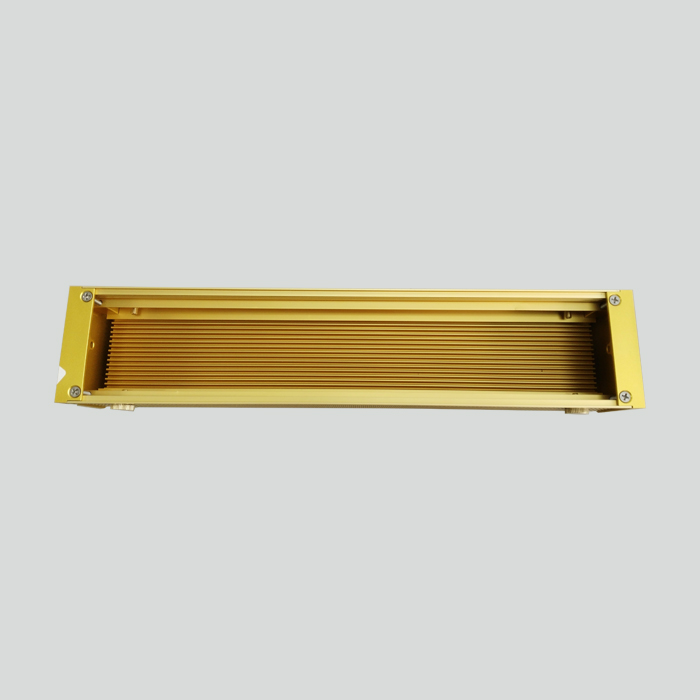

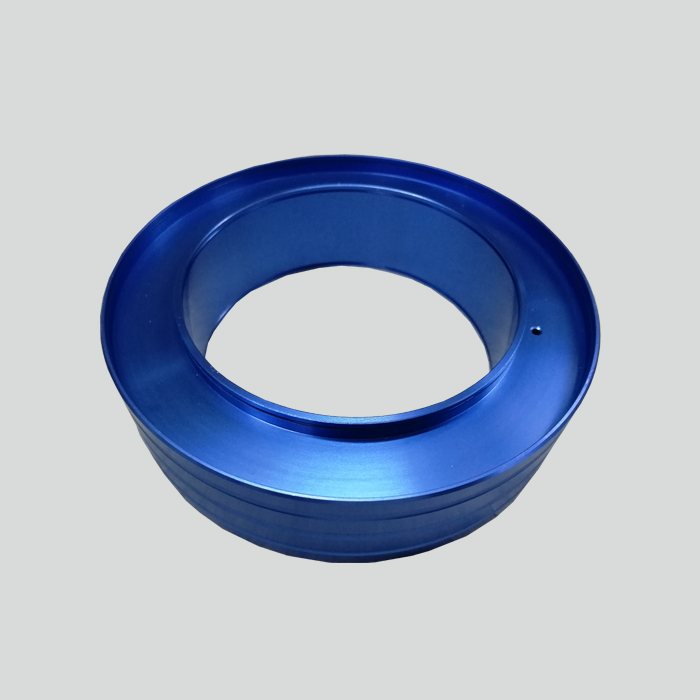

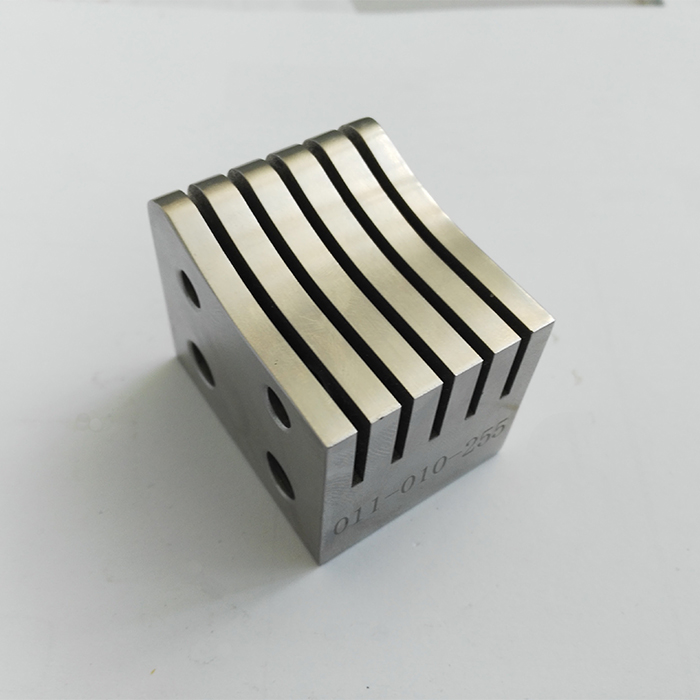

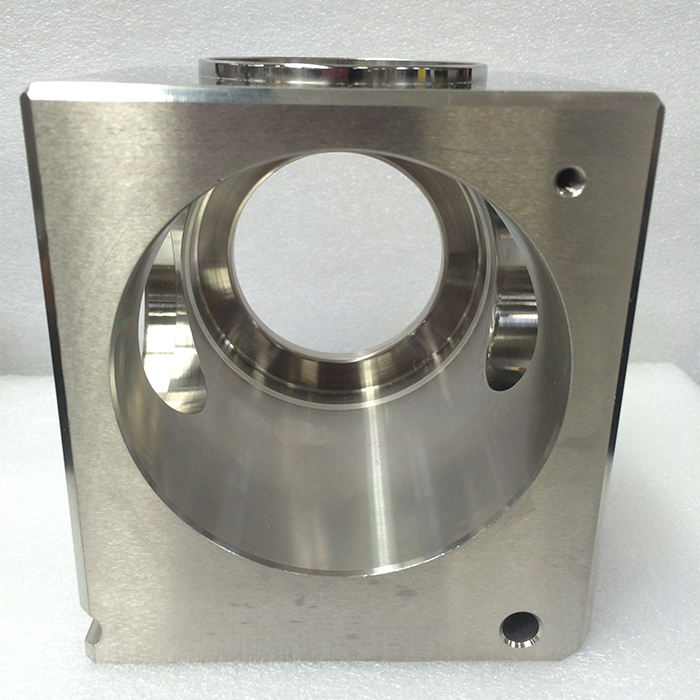

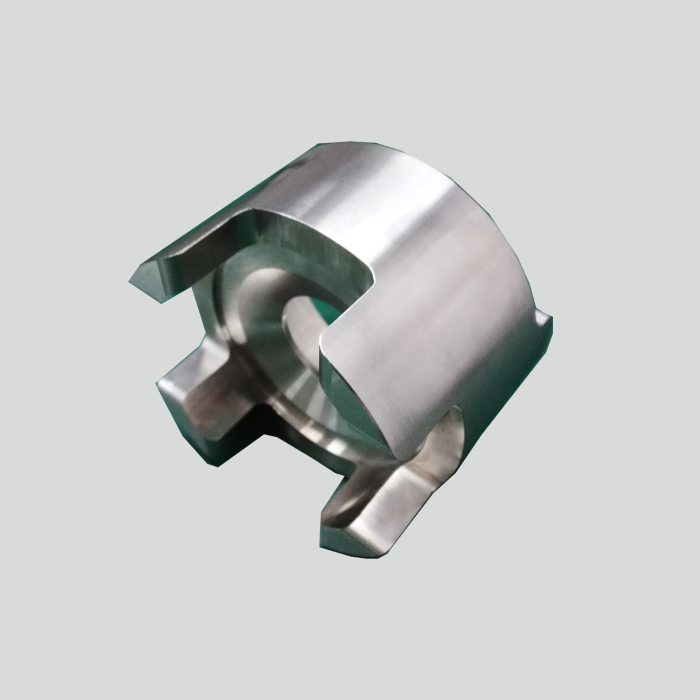

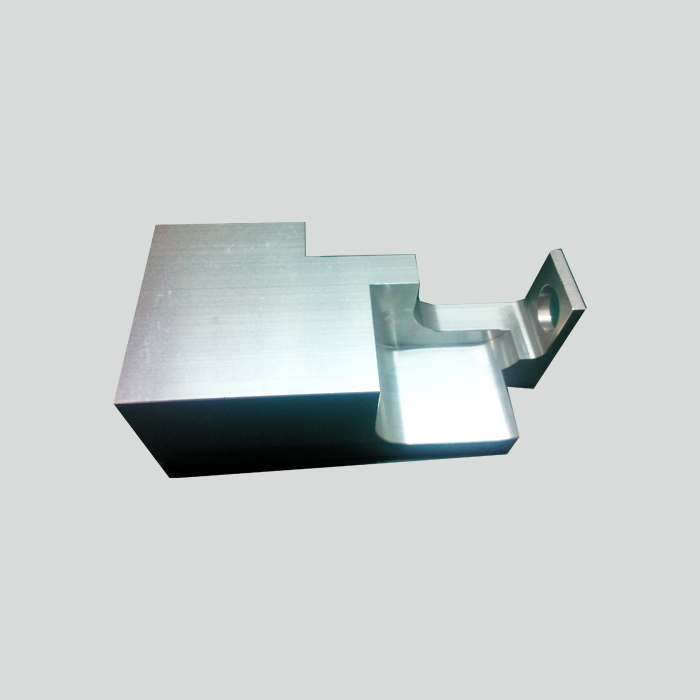

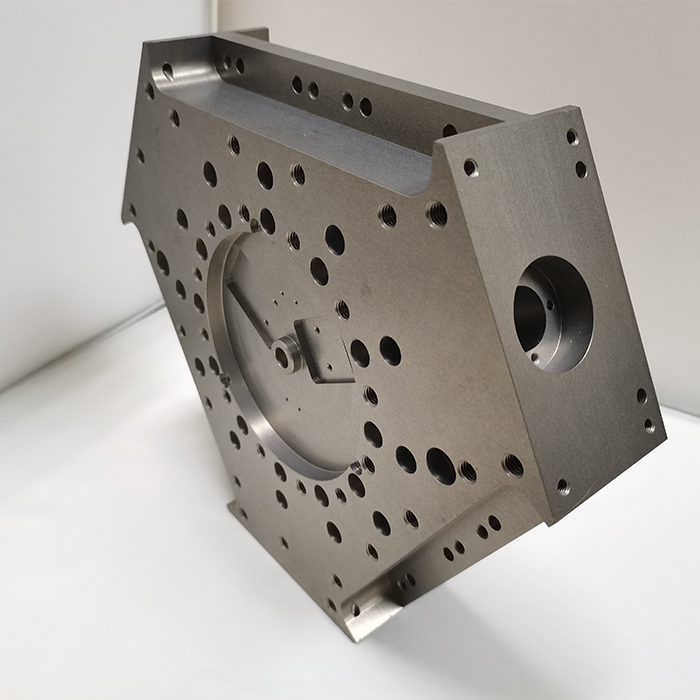

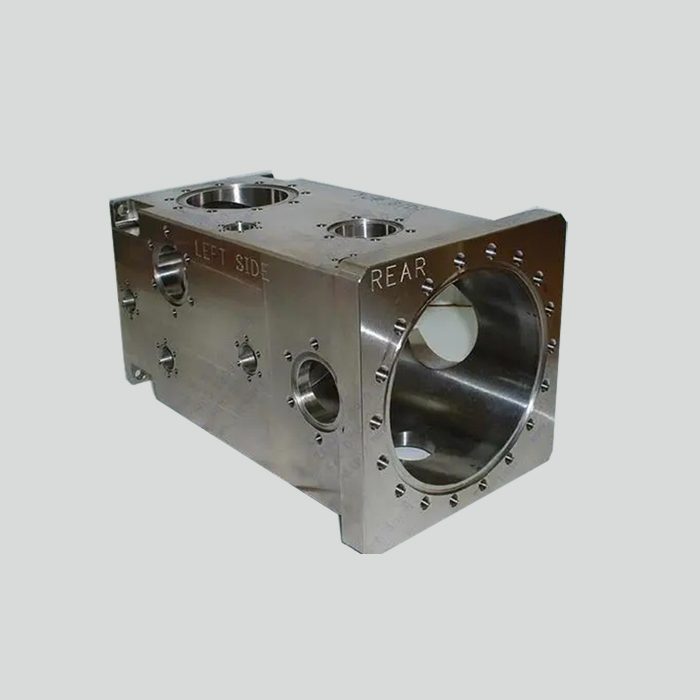

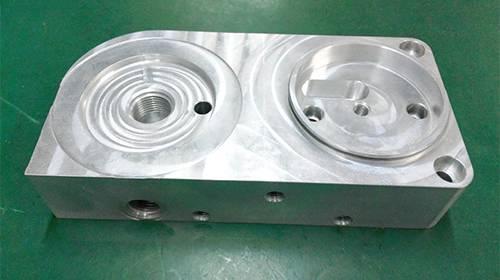

Precision parts recommendation

Professional solutions

Xinda Precision Hardware

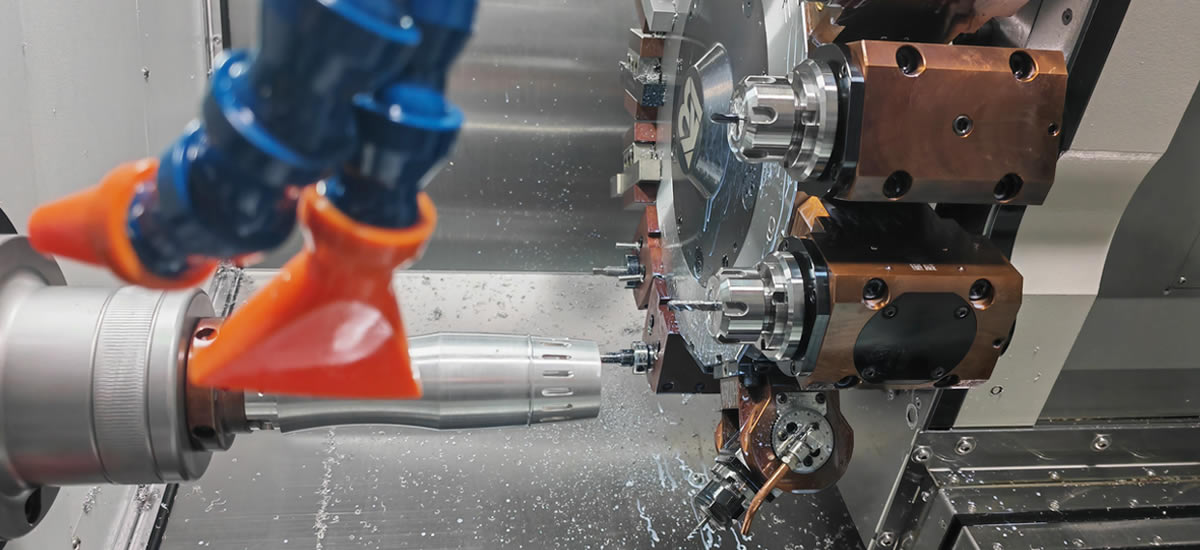

Craftsmanship creates exquisite quality The company focuses on technological and product innovation, combining customer needs to precisely control every manufacturing process and provide customers with the best products and services See more +Four major advantages

◎ Self production, direct sales from manufacturers, providing you with high-quality products and services.

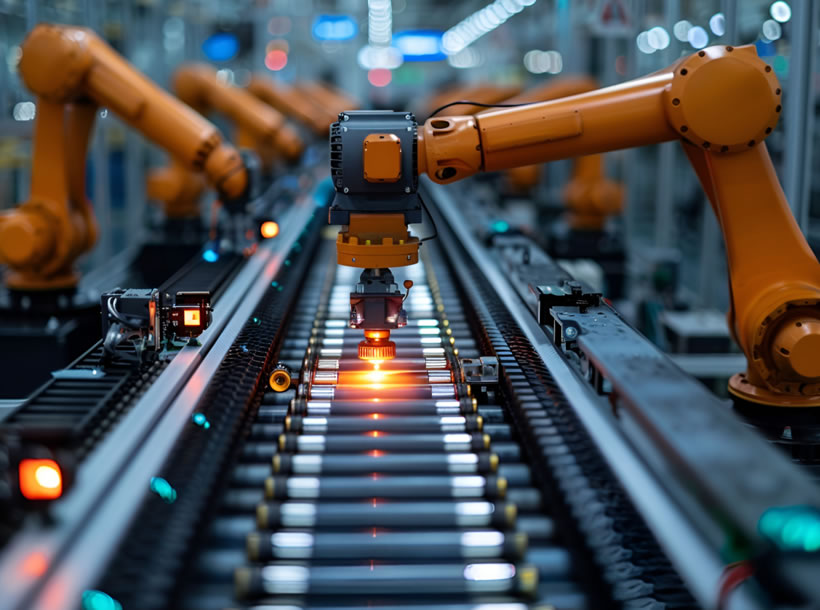

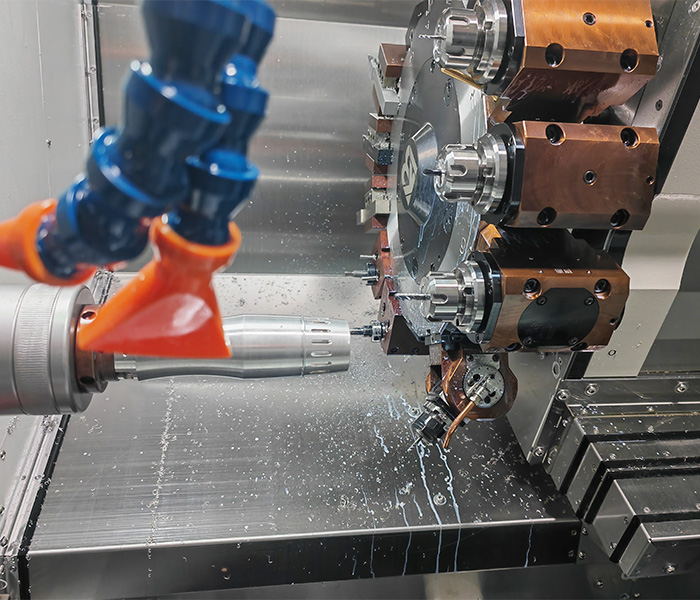

◎ Multiple professional technicians, in collaboration with specialized equipment, continuously update their technology.

◎ The product undergoes strict quality inspection and is confirmed to meet customer requirements and industry standards before shipment.

◎ Experienced team with mature processing and quality control ensures every product's excellence.

◎ Multiple processes, strict quality control, ensuring high quality, reducing product procurement costs by 20% -30%.

◎ The processing accuracy is very high, it can achieve micrometer level processing accuracy, thereby ensuring the quality and stability of the workpiece.

◎ Short production cycle, with a professional delivery team, actively responding to customer feedback needs, and fast delivery.

◎ To provide you with 7*24 hours one to one documentary service, the first time to solve your technical concerns.

Company Profile

Dongguan Xinda Precision Hardware Co., Ltd. was established in 2019 and is located in Dalang, Dongguan, known as the "World Factory". It is a professional company that produces, processes, and sells hardware products, plastic products, mold parts, electronic products, etc. The company's products are involved in industries such as automobiles, automated robots, medical equipment, instruments and meters, manufacturing equipment, aerospace, etc.

With its high-precision quality requirements, it has won high praise from customers. The company adheres to the business philosophy of "customer first, quality first" and strives to provide customers with higher quality products and services.

-

Company ProfileCompany Profile

-

Corporate cultureCorporate culture

-

Corporate imageCorporate image

-

VideoVideo presentation

-

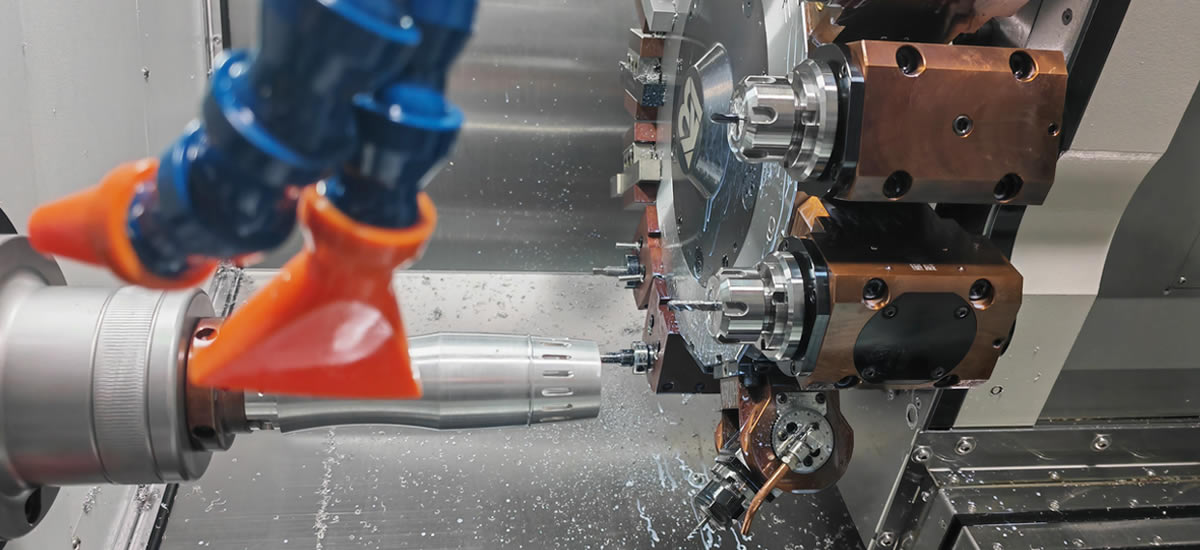

experience

10 + More than 10 years of experience in the industry -

team

30 + Senior engineering team members -

Satisfaction level

90 % Provide professional services -

Use case

300 + Accumulated cases of 300+customers

service process

Xinda · News Center

Contact information

- Contacts: Mr. Deng 86 139 2853 4050

- Contacts: Miss Zhang 86 135 5667 8843

- Q Q: 29928133

- Address: Room 107, No. 3 Derong Road, Dalang Town, Dongguan City, Guangdong Province

- Website: en.cnxdtech.com

QR code