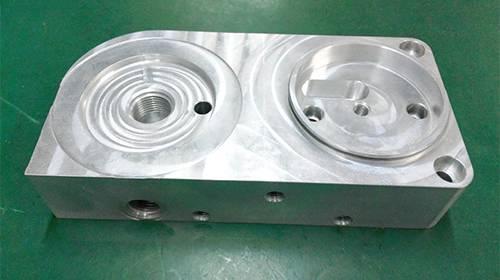

The maintenance of CNC high-precision products is the key to ensuring their long-term stable operation and maintaining high-precision machining quality. Here are some specific measures and suggestions for the maintenance of CNC high-precision products:

1、 Environmental control

Temperature and humidity: CNC equipment should be placed in an environment with a temperature controlled between 15 ° C and 35 ° C and moderate humidity to prevent equipment performance degradation caused by excessive temperature and humidity changes

Cleanliness: Maintain the cleanliness of the surrounding environment of the equipment, avoid impurities such as dust and metal powder from entering the interior of the equipment, and prevent them from affecting the normal operation of electrical components and mechanical parts

2、 Daily cleaning

External cleaning: After daily work, use a clean soft cloth or vacuum cleaner to clean the dust and iron filings on the surface of the machine tool, especially on the control panel, spindle taper hole, tool cart, tool magazine, and other parts

Internal cleaning: Regularly clean the cutting area, sliding surface, and oil groove inside the machine tool to ensure no debris residue. For areas that are difficult to reach, professional tools or compressed air can be used for cleaning

3、 Lubrication and Inspection

Lubrication system: Regularly check the level and quality of lubricating oil and coolant to ensure they meet equipment requirements. For components that require lubrication, such as guide rails, screws, etc., regular lubrication should be carried out according to the requirements of the equipment manual

Check the electrical system: Check whether the electrical connections are loose, whether the wires are damaged, and whether the electrical components are overheated or abnormal. Ensure that the cooling fans of key components such as CNC systems and servo drives are working properly

4、 Accuracy check and adjustment

Machine tool accuracy: Regularly use measuring instruments to check the geometric accuracy and machining accuracy of the machine tool, such as straightness, parallelism, perpendicularity, etc. When a decrease in accuracy is detected, timely adjustment and calibration should be carried out

Tool wear: Regularly check the wear of tools and replace severely worn tools in a timely manner to ensure machining accuracy and efficiency

5、 Standardized operation and training

Develop operating procedures: Develop detailed operating procedures for CNC equipment, including startup preheating, machining parameter settings, shutdown steps, etc., to ensure that operators follow the procedures for operation

Personnel training: Regular training should be provided to operators to understand the usage methods and maintenance knowledge of the equipment, and to improve their operational skills and maintenance awareness

6、 Regular maintenance and upkeep

Regular maintenance plan: Based on the usage of the equipment and the manufacturer's recommendations, develop a detailed regular maintenance plan, including weekly, monthly, and annual maintenance content and requirements

Professional maintenance: For professional maintenance or repair work, it should be carried out by professional engineers to ensure maintenance quality and equipment safety

7、 Other precautions

Avoid abnormal wear and tear: During the machining process, avoid using materials beyond the processing range of the equipment to prevent damage to the machine tool

Power protection: Provide stable power supply for CNC equipment and install voltage stabilizing devices and filters to reduce the impact of power fluctuations and electrical interference on the equipment

In summary, the maintenance of CNC high-precision products is a comprehensive task that requires starting from multiple aspects such as environmental control, daily cleaning, lubrication and inspection, accuracy inspection and adjustment, standardized operation and training, regular maintenance and upkeep, etc., to ensure the long-term stable operation of equipment and high-precision machining quality

Contact information

- Contacts: Mr. Deng 86 139 2853 4050

- Contacts: Miss Zhang 86 135 5667 8843

- Q Q: 29928133

- Address: Room 107, No. 3 Derong Road, Dalang Town, Dongguan City, Guangdong Province

- Website: en.cnxdtech.com

QR code