There are significant differences between five axis linkage machining centers and four axis linkage machining centers in multiple aspects, mainly reflected in machining capabilities, machining accuracy, programming difficulty, and application fields. The following is a detailed analysis of the differences between the two:

1、 Processing capability

Four axis linkage machining center: A four axis machining center is an additional rotating axis added to the traditional three-axis (X, Y, Z) machining foundation. This rotation axis can be the A-axis rotating around the X-axis, the B-axis rotating around the Y-axis, or the C-axis rotating around the Z-axis. This rotating axis enables the machining platform to rotate, allowing the machine tool to complete more automated machining actions during the machining process, achieve multi-faceted machining, reduce clamping times, and improve machining efficiency

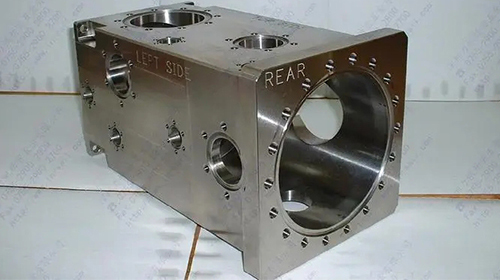

Five axis linkage machining center: A five axis linkage machining center is an additional rotating axis added on the basis of a four axis machining center. This rotation axis is usually the rotation axis of the tool, allowing the tool to rotate in any direction along the machining surface without being limited by the rotation plane. Therefore, five axis machining centers have stronger machining capabilities when processing complex surfaces and can complete more complex machining tasks

2、 Processing accuracy

Four axis linkage machining center: Although a four axis machining center can achieve multi-faceted machining, its machining accuracy may be limited when machining complex surfaces, as the rotation of the tool is still limited by the rotation plane.

Five axis linkage machining center: During the machining process, the tool can rotate in any direction along the machining surface. This flexibility enables the five axis machining center to have better machining accuracy when processing complex surfaces

3、 Programming difficulty

Four axis linkage machining center: Programming for a four axis machining center is more complex compared to a three-axis machining center, as it requires consideration of the motion of the rotating axis. But compared to five axis machining centers, its programming difficulty is still relatively low

Five axis linkage machining center: The programming difficulty of five axis linkage machining center is relatively high. Programmers need to master more programming skills and knowledge in order to fully utilize the machining capabilities of a five axis machining center. Meanwhile, due to the complexity of the five axis machining center, its debugging and maintenance also require a higher level of technical expertise

4、 Application Fields

Four axis linkage machining center: The four axis machining center is mainly suitable for machining flat parts, such as machine bases, panels, and other workpieces. At the same time, it can also perform some simple surface machining, but compared to five axis machining centers, its ability to machine complex surfaces is weaker

Five axis linkage machining center: The five axis linkage machining center is more suitable for machining complex surfaces and workpieces that require higher machining accuracy, such as aviation engine parts, rotating surfaces, threads, etc. In modern manufacturing, five axis machining centers have become one of the important equipment for processing complex components

In summary, there are significant differences between five axis linkage machining centers and four axis linkage machining centers in terms of machining capability, machining accuracy, programming difficulty, and application fields. When choosing which type of machining center to use, enterprises need to consider comprehensively based on specific machining needs and capabilities

Contact information

- Contacts: Mr. Deng 86 139 2853 4050

- Contacts: Miss Zhang 86 135 5667 8843

- Q Q: 29928133

- Address: Room 107, No. 3 Derong Road, Dalang Town, Dongguan City, Guangdong Province

- Website: en.cnxdtech.com

QR code