There are significant differences between five axis linkage machining centers and six axis linkage machining centers in terms of machining capability, machining accuracy, programming difficulty, and application fields. The following is a detailed analysis of the differences between the two:

1、 Processing capability and axis configuration

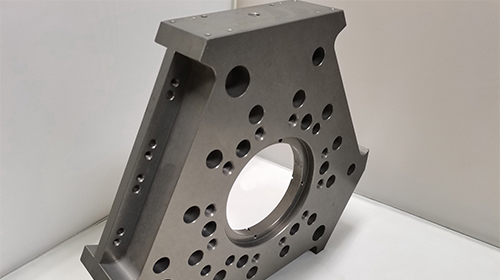

Five axis linkage machining center: A five axis linkage machining center usually includes three linear axes X, Y, and Z, as well as two rotational axes A and B (or any combination of A, C, B, and C axes). These five axes can move simultaneously, achieving complex surfaces and fine hole machining. The flexibility of a five axis machining center enables it to complete various complex machining tasks, such as machining molds, aircraft components, etc

Six axis linkage machining center: The six axis linkage machining center adds a rotation axis on the basis of the five axes, usually the C-axis, which rotates around the Z-axis. This enables the six axis machining center to have higher flexibility and a wider processing range during the machining process. A six axis machining center can handle more complex and precise machining tasks, especially in situations that require high flexibility and precision

2、 Processing accuracy

Five axis linkage machining center: The five axis machining center already has high machining accuracy and can meet the needs of most high-precision machining. However, in some extreme cases, the accuracy of a five axis machining center may be limited to some extent

Six axis linkage machining center: Due to the addition of a rotating axis, the six axis machining center allows the tool to approach the workpiece from more angles during the machining process, thereby reducing interference and collision between the tool and the workpiece. This higher flexibility helps achieve higher machining accuracy, especially for complex surfaces and small features

3、 Programming difficulty

Five axis linkage machining center: The programming of a five axis machining center is relatively complex and requires programmers to have high professional knowledge and skills. During the programming process, it is necessary to consider the coordinated motion between various axes and the optimization of tool paths

Six axis linkage machining center: The programming difficulty of a six axis machining center is higher because adding a rotating axis requires handling more variables and constraints during the programming process. Programmers need to have a deeper understanding of the kinematic and dynamic characteristics of machine tools, as well as the interaction between tools and workpieces

4、 Application Fields

Five axis linkage machining center: Five axis machining centers are widely used in fields such as mold manufacturing, aerospace, and automotive manufacturing. It can process various complex shaped parts and surfaces, meeting the demands of these industries for high-precision and high-quality products

Six axis linkage machining center: Due to its higher flexibility and machining accuracy, six axis machining centers are usually used in fields that require extremely high machining accuracy, such as precision medical equipment, microelectronic devices, etc. Meanwhile, six axis machining centers are also suitable for processing large, complex, and multi-faceted workpieces, such as aircraft engine blades

In summary, there are significant differences between five axis linkage machining centers and six axis linkage machining centers in terms of machining capability, machining accuracy, programming difficulty, and application fields. When choosing which type of machining center to use, enterprises need to consider comprehensively based on specific machining needs and capabilities

Contact information

- Contacts: Mr. Deng 86 139 2853 4050

- Contacts: Miss Zhang 86 135 5667 8843

- Q Q: 29928133

- Address: Room 107, No. 3 Derong Road, Dalang Town, Dongguan City, Guangdong Province

- Website: en.cnxdtech.com

QR code