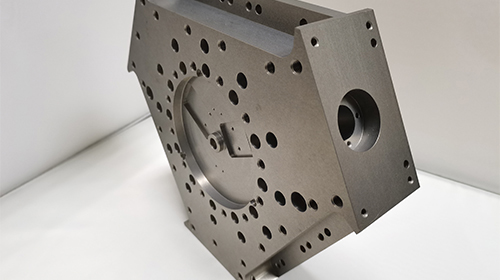

The five axis linkage machining center, as a high-precision and high-efficiency machining equipment, has significant advantages

Higher machining accuracy:

The five axis linkage machining center can perform machining in multiple directions, ensuring consistent accuracy on all surfaces of the workpiece, thereby improving overall machining precision. This high-precision machining capability is particularly important for industries such as aerospace and automotive manufacturing that require high-precision components

Multi dimensional processing capability:

The five axis linkage machining center can perform linear motion in the X, Y, and Z directions, while rotating around two rotation axes, thus enabling the machining of complex surfaces, as well as various shapes such as polygons and grooves. This multi-directional machining capability greatly expands the applicability of machining centers

Improve processing efficiency:

Compared to traditional three-axis machining centers, five axis linkage machining centers can complete multiple machining processes with one clamping, reducing the need for changing processes and fixtures, thereby improving machining efficiency. In addition, five axis machining can reduce the idle time during the machining process, further shortening the machining cycle

Can process complex components:

Due to the multi axis linkage characteristics of the five axis linkage machining center, it can process more complex components. This is of great significance for industries such as automobiles, aerospace, and molds that require high-precision and complex shaped components

Save labor costs:

The automation level of the five axis linkage machining center is high, which can reduce the dependence on manual operation and thus lower labor costs. Meanwhile, automated processing can also improve production efficiency and product quality stability

Reduce processing costs:

By reducing the use of changing processes and fixtures, as well as shortening the machining cycle, the five axis linkage machining center can lower machining costs. In addition, due to the improvement of processing accuracy and the reduction of errors, the scrap rate and post-processing costs can also be reduced

Contact information

- Contacts: Mr. Deng 86 139 2853 4050

- Contacts: Miss Zhang 86 135 5667 8843

- Q Q: 29928133

- Address: Room 107, No. 3 Derong Road, Dalang Town, Dongguan City, Guangdong Province

- Website: en.cnxdtech.com

QR code