The advantages of CNC high-precision products are very significant, which make CNC machining technology occupy an important position in modern manufacturing. The following are the main advantages of CNC high-precision products:

High precision:

CNC machining technology can achieve micrometer level machining accuracy by precisely controlling the movement of machine tools through computers. This is crucial for products that require extremely high precision, such as aerospace components, precision instruments, and medical devices

High efficiency:

Once the CNC program is written and debugged, the machine tool can automatically complete the machining process without manual intervention. This greatly improves production efficiency, shortens production cycles, and reduces the possibility of human errors

High consistency:

CNC machining adopts standardized programming and machining processes, which can ensure that the parts in each production batch have the same high precision and high quality. This consistency is crucial for large-scale production and quality control

Flexibility:

CNC machine tools have extremely high flexibility and can adapt to the processing needs of products of different shapes and sizes by modifying the program. This makes CNC machining technology equally advantageous in small batch and multi variety production

Reduce material waste:

CNC machining can precisely control the cutting amount and shape of materials, thereby reducing material waste and lowering costs. This is particularly important for the processing of expensive materials

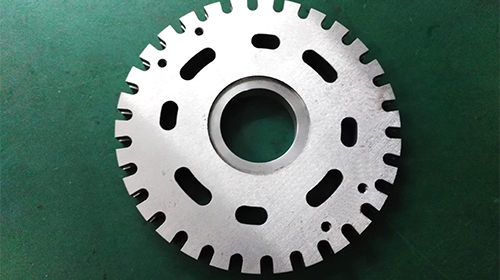

Complex shape processing capability:

CNC machining technology can handle complex geometric shapes and surfaces, which are difficult to achieve with traditional machining methods. This gives CNC machining a unique advantage in manufacturing complex parts and molds

Easy to integrate and automate:

CNC machine tools can be integrated with other automation equipment and software to form a complete automated production line. This further improves production efficiency and reduces reliance on manual operations

Improve product quality:

Due to the high precision and consistency of CNC machining, the overall quality of the product can be significantly improved. This helps businesses enhance their brand image, gain customer trust, and stand out in a fiercely competitive market

Strong adaptability:

CNC machining technology can adapt to the processing of various materials, including metals, plastics, ceramics, etc. This makes CNC machining have broad application prospects in multiple industries

Data traceability:

All data during the CNC machining process can be recorded and traced, which helps companies with quality control and product tracking. When needed, it is possible to quickly identify the cause of the problem and make improvements

In summary, the advantages of CNC high-precision products include high precision, high efficiency, high consistency, flexibility, reduced material waste, ability to process complex shapes, ease of integration and automation, improved product quality, strong adaptability, and data traceability. These advantages make CNC machining technology play an increasingly important role in modern manufacturing

Contact information

- Contacts: Mr. Deng 86 139 2853 4050

- Contacts: Miss Zhang 86 135 5667 8843

- Q Q: 29928133

- Address: Room 107, No. 3 Derong Road, Dalang Town, Dongguan City, Guangdong Province

- Website: en.cnxdtech.com

QR code