4News

2024

-

09

-

23

The maintenance of color anodizing is crucial for preventing fading. Here are some key maintenance measures to ensure that the colored anodized layer remains bright and long-lasting:1、 Environmental control

2024

-

09

-

23

There are significant differences between colored anodizing and ordinary anodizing in multiple aspects, mainly reflected in color generation, application fields, process, and final effects. 1、 Color generation

2024

-

09

-

23

There are significant differences between colored anodizing and ordinary anodizing in multiple aspects, mainly reflected in color generation, application fields, process, and final effects. 1、 Color generation

2024

-

09

-

23

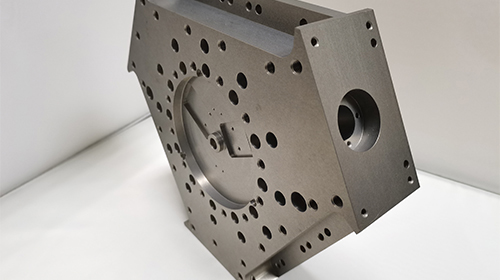

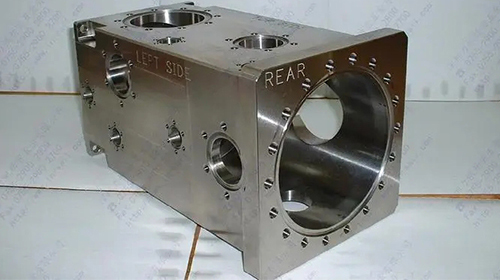

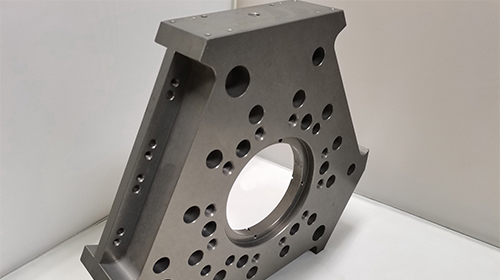

The five axis linkage machining center, as a high-precision and high-efficiency machining equipment, has significant advantages.Higher machining accuracy:The five axis linkage machining center can perform machining in multiple directions, ensuring consistent accuracy on all surfaces of the workpiece, thereby improving overall machining precision. This high-precision machining capability is particularly important for industries such as aerospace and automotive manufacturing that require high-precision components

2024

-

09

-

23

There are significant differences between five axis linkage machining centers and four axis linkage machining centers in multiple aspects, mainly reflected in machining capabilities, machining accuracy, programming difficulty, and application fields. The following is a detailed analysis of the differences between the two:

2024

-

09

-

23

There are significant differences between five axis linkage machining centers and six axis linkage machining centers in terms of machining capability, machining accuracy, programming difficulty, and application fields. The following is a detailed analysis of the differences between the two:

Contact information

- Contacts: Mr. Deng 86 139 2853 4050

- Contacts: Miss Zhang 86 135 5667 8843

- Q Q: 29928133

- Address: Room 107, No. 3 Derong Road, Dalang Town, Dongguan City, Guangdong Province

- Website: en.cnxdtech.com

QR code

Copyright @ Dongguan Xinda Precision Hardware Co., Ltd

Technical support:【Dongguan website construction】

【Admin】